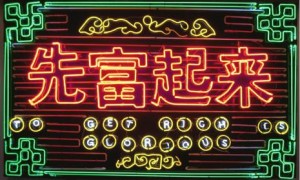

Deng Xiaoping has been credited for coining the phrase “To get rich is glorious!” It is not clear whether he actually said it, and if he did whether he could have ever foreseen the speed of the rise of the Red Dragon.

China’s emergence as a manufacturing powerhouse has been startling. The country not only overtook the United States in 2011 to become the world’s largest producer of manufactured goods, but also used its huge manufacturing engine to boost living standards by doubling the country’s GDP per capita over the last decade. That achievement took the industrialising United Kingdom 150 years.

But the era of cheap China is drawing to a close. Since 2001, hourly manufacturing wages in China have risen by an average of 12 percent a year and continue to rise.

source: tradingeconomics.com

Increases in taxes and a tightening of environmental and welfare regulations have all played a part. However, the largest contributing factors are rising wages, labour shortages and a steady growth in consumer spending power. Add to this all the other elements that affect the make up of product cost and the result is increased risk and an entire supply chain under pressure.

Global sourcing companies have responded in different ways to the changes in China. Some have chosen to follow the ‘China Plus One’ approach and look for production facilities in other Southeast Asian countries. Others have moved their sourcing networks to China’s interior, where wages continue to be lower than those on the coast. But more often than not the move can result in a zero-sum game – it takes longer and costs more to ship products from the Chinese heartland to overseas markets.

It is not the strongest of the species that survives, nor the most intelligent, but the one most responsive to change ~ Charles Darwin.

In a push to find more favourable sourcing territories and innovative manufacturing solutions that deliver the right price to clients, Hunter have used their deep understanding of the Asian manufacturing market to identify and develop scalable alternatives. In China, we have worked with our existing partners to install automation where possible, and the initial results are promising. In 2013 we were able to deliver a 12% reduction in manufacturing cost on a high-end box for a well-known luxury watchmaker. This particular pack went on to win the Luxury Packaging Award 2014.

At the same time, we have embarked on a strategic search across the region, looking beyond China to secure alternative manufacturing solutions. Our strict approach to risk management has allowed us to find reliable partners, without compromising compliance and speed to market.

The pace of change in China has been so astonishing that it is hard to keep up. The deep-seated stereotypes about sweatshops are a thing of the past. Only those sourcing companies that have combined smart investment in existing China facilities with a look beyond the Chinese horizon are well placed to take on the many challenges that lay ahead.

The story will be forever unfolding. By investing the time and expertise necessary to strike the right balance, we are confident that our supply chain is as robust and cost effective as it has ever been.